| Advisory note | 07/2023 |

|---|---|

| For | Licensees and contractors working in the gasfitting industry |

| Scope | Applies to all areas in New South Wales |

Issue

Recent gas audit inspections of Class 1 and 2 buildings carried out by NSW Fair Trading’s Gas Compliance Unit have identified gas pipes that have been damaged either prior to or during the installation process.

A new revision of AS/NZS5601.1 has been released on 30 September 2022 (AS/NZS5601.1:2022) and becomes the referenced standard from 30 March 2023.

AS/NZS5601.1:2022 requires that a gas pipe installed in a metal frame shall have holes drilled or formed to an accurate size and grommets, insulation or a short sleeve of oversize pipe firmly secured to the framework and inserted around the pipe.

All gas installations in NSW must comply with the Gas and Electricity (Consumer Safety) Act 2017 with any installation not conforming to AS/NZS 5601.1:2022 considered non-compliant.

Reference

Gas and Electricity [Consumer Safety] Regulation 2018

AS/NZS 5601.1:2022 - Gas Installations

5.1.1 – Condition of pipe and pipe fittings

Pipe and pipe fittings shall be clear and free from cutting burs, defects in structure or threading, cutting oil or grease, weld or braze deposits, flux residues and other such contaminants.

5.1.9 – Bending pipe

Every bend and offset in a pipe shall be free from any buckle, crack, or other evidence of physical damage to the pipe or its protective coating.

5.3.3 – Piping not to be subject to physical damage

In locations where physical damage may occur, consumer piping shall be protected by appropriate means including, but not limited to:

(a) sleeving;

(b) barriers; or

(c) covering

5.3.14.4 – Metal framework

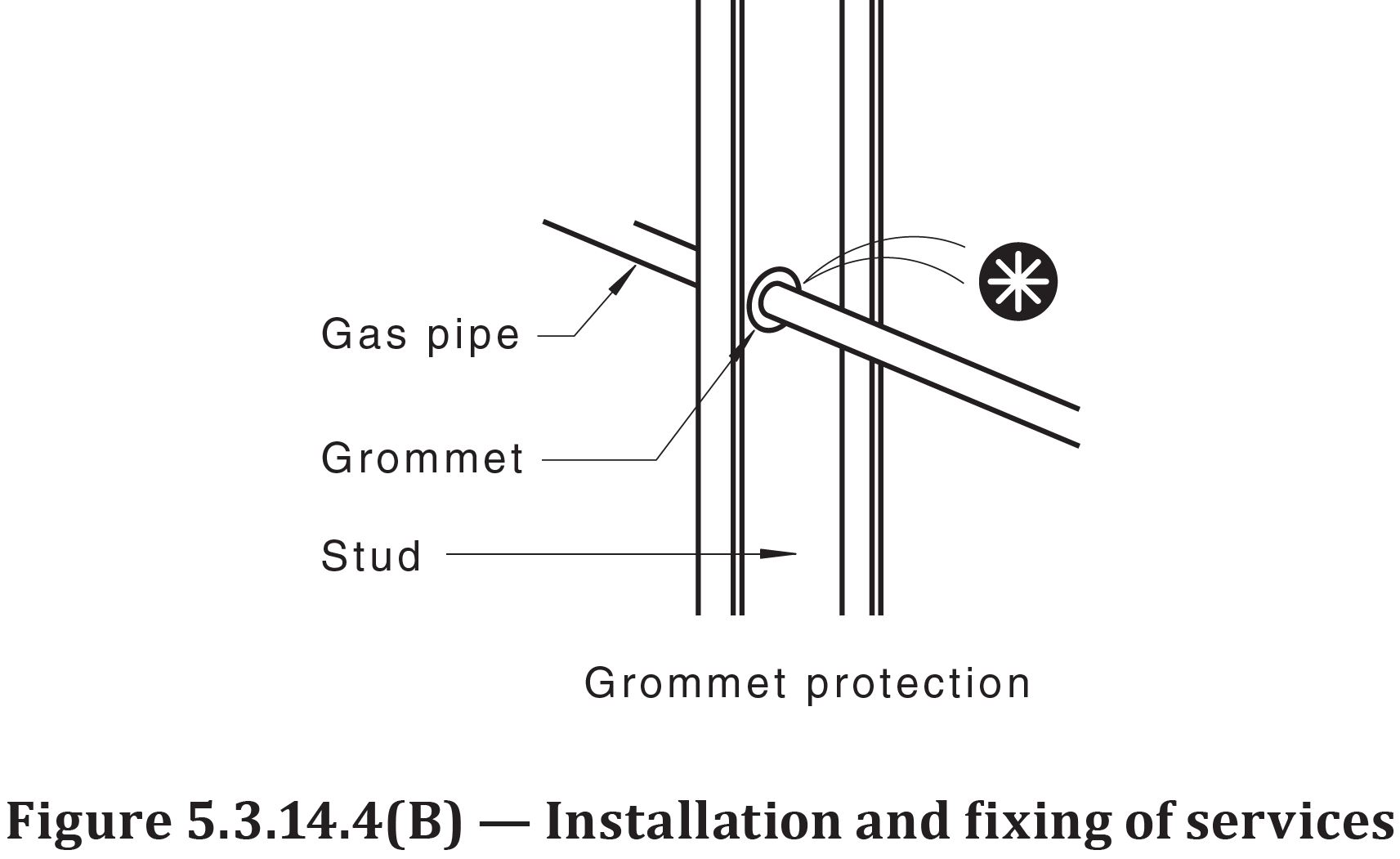

Holes drilled or formed in metal studs or plates shall be accurately sized to enable suitable grommets, insulation or short sleeve of oversize pipe firmly secured to the framework to be inserted around the pipe, to ensure no direct contact between the pipe and framework but to allow free longitudinal movement of the pipe through the grommet, lagging or sleeve, as shown in figures 5.2.14.4(A) and 5.3.14.4 (B)

Figure 5.3.14.4 (B) below

Requirements

The gas consumer pipe must be installed free from any buckle, crack, or other evidence of physical damage. Due care must be taken during installation not to damage any part of the pipe and fittings.

Below are examples of identified non-compliances

Example 1: The gas multilayer pipe has been kinked when forming the bend.

Example 2: The gas multilayer pipe has been damaged when sliding the pipe through the hole in the metal frame. Also, there is no grommet installed to protect the pipe.

Example 3: The gas multilayer pipe has been damaged during installation. Insufficient care taken when dragging the pipe past the metal joists.

For more information, please email:[email protected]

This advisory note has been approved for issue by the BSCU Technical Review Committee. Information contained within this document is current as of January 2023 and refers to codes and standards current at the time of writing.

NSW Fair Trading disclaims any liability (including for negligence) to any person in respect of anything done, or not done, by that person in whole or partial reliance on any of the information in this advisory note.